Robot frame #1 was completely reinforced with cross-braces and mounting brackets for the drivetrain.

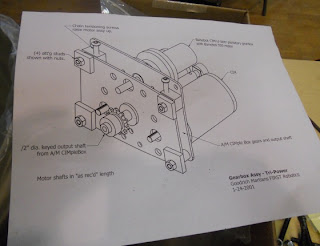

Per the exploded part drawings that were generated from our CAD team, the gearbox assembly and drivetrain components were also assembled and installed into frame #1. We are calling this years design, the "tri-power", as 3 motors on each side of the chassis power the drivetrain system.

As expected, more drilling and tapping was needed for some drivetrain attachments as well. Many design tweaks are made 'on the fly'!

Our first end effector prototype was ready for a test at 10 PM and the excitement was high!

Step one was to mount our roller mockup to last years robot chassis and test the mechanisms that will rotate toward each other to pick up the game peices, and away to release them. The candy cane striped material on the rollers is a urethane belt which is quite tacky and yeilds itself well to this capture application.

Step two was to try out the pick up and release functions with the game peices (inflated circle, square and triangles in the shape of the FIRST Robotics Logo).

One of our Lead Mentors is trying on the game peice for size in this photo!

After careful tryout

and discussion, it

was decided that

the rollers should be adjusted inboard to prevent

entrapment and

enhance the release of

the game peice.

Step three was to mount the roller mockup lower on the chassis to simulate its designed playing position in which it will pick up game pieces from the floor.

Finally, at 10:19 PM, a successful capture and release of the gamepeice! A simple solution to an interesting challenge and a beautiful end to a very long day!

No comments:

Post a Comment